Table of Contents

LEGO Rotary Inverted Pendulum Ver. 2.0

Author: Sangsin Park Email: sangsin.park@unlv.edu

Date: Last modified on 05/19/2017

Keywords: Rotary inverted pendulum, LEGO brick, and NXC

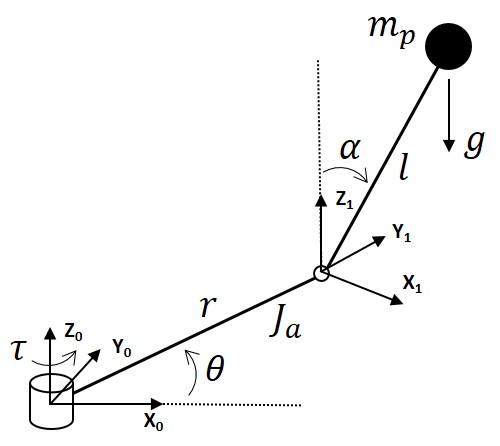

Modeling of the rotary inverted pendulum

The rotary inverted pendulum has one motor on the base joint and two encoders on each joint.

The encoders measure angular displacements of a swing arm and a pendulum.

I assume that the joint friction and the viscous damping of the motor are neglected.

At a swing arm, r, Ja, θ, and τ are a link length, a moment of inertia of the swing arm, an angular displacement, and a joint torque, respectively. At a pendulum, l, mp, α, and g are a link length, a pendulum mass, an angular displacement, and gravity acceleration, respectively.

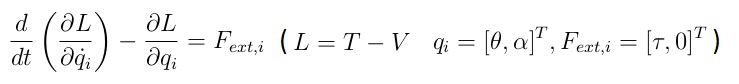

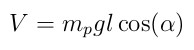

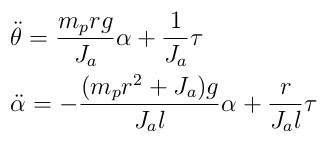

Equations of motion

Euler-Lagrange equation is used for derive equations of motion.

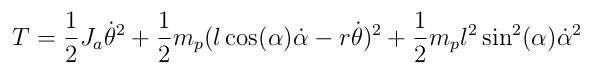

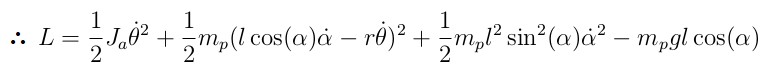

The kinetic energy of the system is

- HW. Derive the kinetic energy.

And the potential energy of the system is

Then the Lagrangian is same as the following.

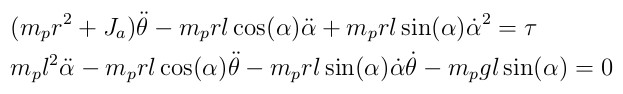

From Euler-Lagrange equation, the equations of motion are

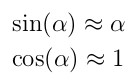

For linear control, we need to linearize the equations about near the equilibrium point (α = 0 ).

Assume that α is a small angle. Then,

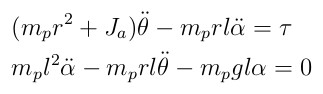

Therefore the linearized equations of motion are

- HW. Linearize the above nonlinear equations by Taylor expansion.

For state-space representation, the equations are reconstructed.

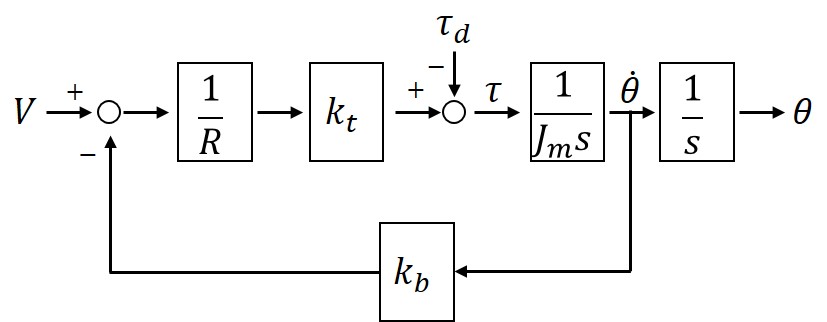

It needs to transform the input torque into the motor voltage because the torque can not be used by the input in the lego system. So the following DC motor model is needed to do that. If a motor inductance and viscous damping can be neglected,

where, R, kt, Jm, and kb are a motor resistance, a torque constant, a motor armature inertia, and a back-emf constant, respectively.

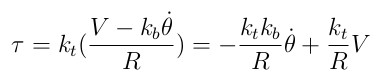

Assume that an external torque is neglected and then the motor torque is

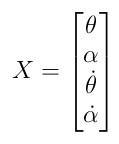

Let's substitute this motor torque into the equations of motion and set states X.

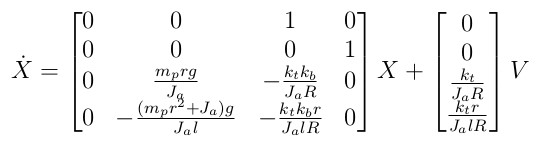

Therefore, the state-space representation for full-state feedback control is shown

- HW. Derive a transfer function assuming that an output, y, is a α.

Full state feedback control

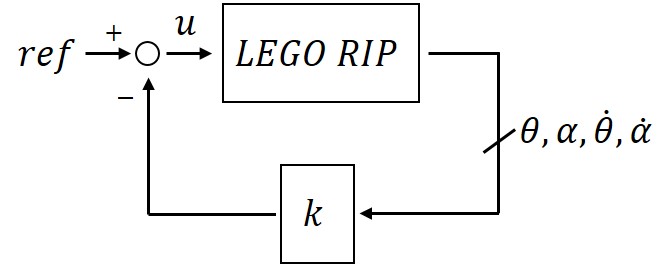

To control the LEGO RIP, a full state feedback controller is used.

where, ref, k, and u are a reference input, a feedback gain vector, and a control input, respectively.

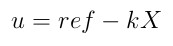

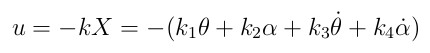

A control law is

, and since we desire that the pendulum keeps upright, the ref is equal to zero.

where k1, k2, k3, and k4 are gains of a swing arm angle, a pendulum angle, a swing arm angular velocity and a pendulum angular velocity.

Now we need to determine these gains.

LQR for the gains

Matlab Code

clear, clc, close all mp=((2*0.36335)+(2*1.33192)+0.56)/1000; %Pendulum Mass r=140/1000; %Arm Length L=209/1000; %Pendulum Length g=9.81; %Gravity ma=(0.66556+1.33192)/1000; % Arm mass Ja=(1/3)*ma*(r^2); % Arm moment of inertia R=9.05; %DC-motor armature resistance kt=0.26; %DC-motor torque constant kb=0.26; %DC-motor back-emf constant A=[0 0 1 0; 0 0 0 1; 0 mp*r*g/Ja -kt*kb/Ja/R 0; 0 -(mp*r^2 + Ja)*g/Ja/L -kt*kb*r/Ja/L/R 0]; B=[0; 0; kt/Ja/R; kt*r/Ja/L/R]; q1 = 50; %Weight on motor position q2 = 50; %Weight on pendulum position q3 = 50; %weight on motor velocity q4 = 300; %weight on pendulum velocity Q = diag([q1 q2 q3 q4]); R = 1; K = -lqr(A,B,Q,R); display(K);

K = -7.0711 -361.6049 -7.2061 -9.1540

NXC code for LEGO NXT Brick

#define MOTOR OUT_A #define PNDLM OUT_C #define FULL_SPEED 100 #define D2R 0.0175 // converts degree to radian #define R2D 57.2958 // converts radian to degree long prev_tick = 0; long prev_Mdeg = 0; long prev_Pdeg = 0; long Mdeg = 0; long Pdeg = 0; long M_diff = 0; long P_diff = 0; float dt = 0.0; float GTime = 0.0; float Mrad = 0.0; float Prad = 0.0; float d_Mrad = 0.0; float d_Prad = 0.0; float d_Mdeg = 0.0; float d_Pdeg = 0.0; float M_errSum = 0.0; char controlU = 0; bool flag_balanceControl = true; byte fileHandle; sub MotorPID(float refRad, float PGain, float IGain, float DGain) { float error = refRad - Mrad; float U = PGain*error + IGain*M_errSum - DGain*d_Mrad; if(U > FULL_SPEED) { controlU = FULL_SPEED; } else if(U < -FULL_SPEED) { controlU = -FULL_SPEED; } else { controlU = U; } M_errSum = M_errSum + error - 1.0*(U - controlU); OnRev(MOTOR, controlU); } sub MotorOpenLoop(float speed) { if(speed > FULL_SPEED) { controlU = FULL_SPEED; } else if(speed < -FULL_SPEED) { controlU = -FULL_SPEED; } else { controlU = speed; } OnRev(MOTOR, controlU); } task ReadEncoder() { const int w = 4; float M_mov[w] = {0.0,}; float P_mov[w] = {0.0,}; float sum_Mmov = 0.0; float sum_Pmov = 0.0; int cnt = 0; while(true) { dt = (CurrentTick() - prev_tick)*0.001; Mdeg = MotorRotationCount(MOTOR); Pdeg = MotorRotationCount(PNDLM); M_diff = Mdeg - prev_Mdeg; P_diff = Pdeg - prev_Pdeg; prev_Mdeg = Mdeg; prev_Pdeg = Pdeg; d_Mdeg = M_diff/dt; d_Pdeg = P_diff/dt; Mrad = Mdeg*D2R; Prad = Pdeg*D2R; d_Mrad = d_Mdeg*D2R; d_Prad = d_Pdeg*D2R; prev_tick = CurrentTick(); GTime += dt; Wait(MS_20); } } task BalanceControl() { // A physical motor rotation direction is reversed as a model's rotation direction. float Gm_p = -(-7.07106781265702); //Gain on Motor Position float Gp_p = -361.604865668371; //Gain on Pendulum Position float Gm_v = -(-7.20613568524004); //Gain on Motor Velocity float Gp_v = -9.15404034187486; //Gain on Pendulum velocity Wait(MS_10); while(true) { if(flag_balanceControl == true) { MotorOpenLoop(Gp_p*Prad + Gp_v*d_Prad + Gm_p*Mrad + Gm_v*d_Mrad); } Wait(MS_20); } } task Display() { while(true) { TextOut(0, LCD_LINE1, FormatNum("Frq: %.1f Hz", 1/dt), DRAW_OPT_CLEAR_LINE); TextOut(0, LCD_LINE2, FormatNum("P deg: %d", Pdeg), DRAW_OPT_CLEAR_LINE); TextOut(0, LCD_LINE3, FormatNum("M deg: %d", Mdeg), DRAW_OPT_CLEAR_LINE); TextOut(0, LCD_LINE4, FormatNum("Time: %.3f", GTime), DRAW_OPT_CLEAR_LINE); TextOut(0, LCD_LINE5, FormatNum("Flag_B: %d", flag_balanceControl), DRAW_OPT_CLEAR_LINE); TextOut(0, LCD_LINE6, FormatNum("Ctrl U: %d", controlU), DRAW_OPT_CLEAR_LINE); Wait(MS_200); } } task WriteData() { short bytesWritten; string write; long cnt = 0; CreateFile("data_sp.txt", 51200, fileHandle); while(true) { ++cnt; write = NumToStr(cnt); write = StrCat(write, " ", NumToStr(GTime), " ", NumToStr(Mrad), " ", NumToStr(d_Mrad), " ", NumToStr(Prad), " ", NumToStr(d_Prad)); WriteLnString(fileHandle, write, bytesWritten); Wait(MS_5); } } task main() { DeleteFile("data_sp.txt"); prev_tick = CurrentTick(); Precedes(ReadEncoder, BalanceControl, Display); //Precedes(ReadEncoder, Display); //Precedes(ReadEncoder, WriteData, Display); //Precedes(ReadEncoder, BalanceControl, WriteData, Display); }